How to measure firmness / softness

Firmness and softness: definition and importance

Firmness and Softness represent two ends of a spectrum of textural properties. A soft product exhibits slight resistance to deformation and soft materials require less force to compress and deform more readily, while a firm product shows moderate resistance – it is the inverse of softness. In contrast, hardness indicates substantial resistance to deformation. These properties are relevant across many industries, and the terms "firmness" or "softness" are often preferred depending on the product type. These properties are important in evaluating the texture of various materials, particularly in food products (e.g., fruits, baked goods, gels), cosmetics (e.g., creams, lotions), and industrial materials (e.g., rubber, foam).

A variety of tests can be used to measure these properties, such as compression, penetration, extrusion, or cutting tests where a probe/attachment pushes down on a sample and the resulting force is recorded. Related properties to firmness or softness, are spreadability, biting force/cutting force, consistency, rupture force, gel strength, compressibility and toughness.

Further example applications of firmness and softness testing

Firmness and softness measurements using a Texture Analyser are essential for evaluating mechanical properties across various industries. Below are key applications:

- Fruit firmness testing: Evaluating the firmness of fruits such as apples and tomatoes to assess ripeness by measuring the force required to penetrate the skin or flesh. Softer fruits tend to be overripe, while firmer fruits are typically fresher.

- Bakery product testing: Assessing the firmness of baked goods like bread and cakes by measuring the force needed to compress a slice or bite into a cake. The crust of bread can be firm, offering resistance before the probe breaks through. The crumb (interior) of soft bread will deform easily, showing low resistance on a graph.

- Cosmetic product evaluation: Testing the firmness of cosmetics like creams, gels, lipsticks or waxes by measuring the force required to penetrate them.

- Gel and gelatinous product testing: Measuring the firmness or softness of gel-based products like pharmaceutical gels and gelatine desserts by assessing the force needed to penetrate them.

- Meat and poultry texture testing: Assessing the tenderness of meat and poultry products by measuring the force needed to puncture a cooked meat sample.

- Solid dairy product texture analysis: Evaluating the texture of yoghurt and dairy products, such as cheese, by measuring the force needed to penetrate the surface or compress/cut a sample to assess their softness. In cheese production, firmness is measured to ensure the desired texture, ranging from soft, spreadable cheeses to firm, sliceable varieties. A hard cheese like Parmesan will show high firmness, with a steep rise in force as the probe compresses it.

- Candy and confectionery texture testing: Measuring the firmness and softness of candies and chocolates by assessing the force required to bite or compress them.

- Textile material softness: Evaluating the softness of fabrics, cushioning properties of mattresses and upholstery and clothing by measuring the force required to deform a fabric sample, assessing its comfort.

- Rubber and foams: The firmness of rubber and foam materials is crucial for applications like cushions, mattresses, and insoles. The firmness affects the material’s ability to absorb impact and provide support.

In these examples, a Texture Analyser applies controlled forces/distances to measure the firmness or softness of products, helping ensure quality control, consistency, and compliance with desired texture standards across industries.

Typical probe/attachment used for measurement

In a typical firmness/softness measurement test, a compression or penetration test is performed, where a probe/s is pressed onto/into the sample at a constant speed to a specified depth or force.

Compression

The physical nature of some products make them more suitable for measuring firmness/softness via a compression test. Generally, the higher the force to compress (taken at the maximum force, or a suitable distance prior to the maximum force) the firmer the sample. For the repeatable assessment of products using a compression test, the sample must be repeatable in size and shape, as a compression test (by rule) completely encloses the product.

Bulk compression

Where sample pieces are not so repeatable in size and shape (or are non-homogeneous) such as breakfast cereals, a number (or chosen weight) of pieces may be taken and tested together in a 'bulk compression' test. This serves to create an averaging effect for a firmness/softness measurement.

Sometimes you wish to measure the firmness/softness in the same way that a consumer would perceive this property. For example, when choosing bread at the supermarket it is common to squeeze it in your hand.

The testing of eye pencils using an Eye Pencil Rig is also an imitative compression test.

Penetration

The physical nature of some products make them more suitable for testing via a penetration test. Generally, the higher the force to penetrate, the firmer the sample. A penetration test may often be chosen over a compression test for the following reasons:

a) Where the product is not repeatable in size and shape, but has a certain repeatable facet of its surface to which a small penetration probe can repeatedly be applied. For example, in the testing of an apple, apples are not normally perfectly identical in size and shape. By using a penetration probe to test, the apple could have a diameter of e.g. 60-300mm without any effect on the repeatability of the test.

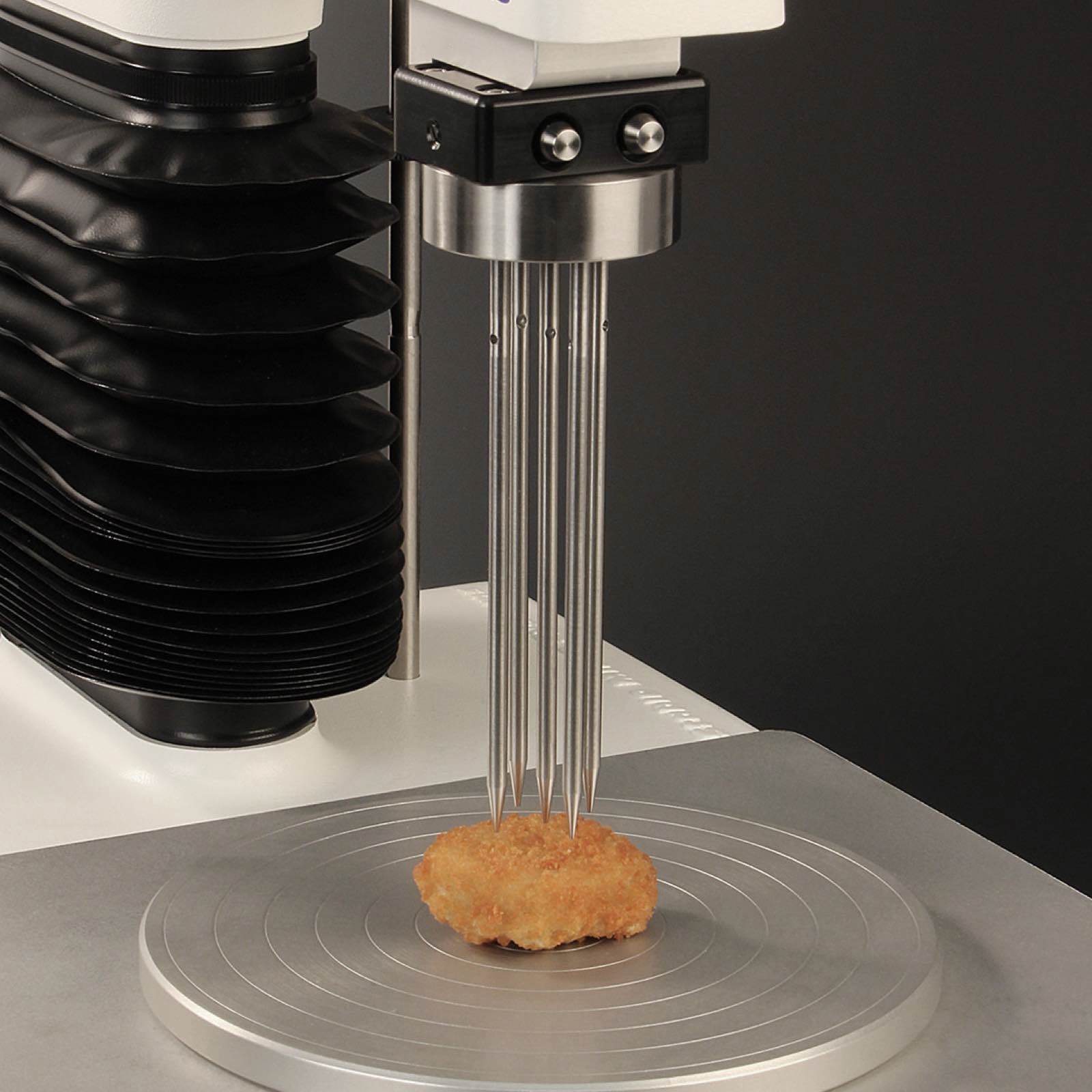

b) Where assessment of the internal structure of a product is more desirable. A penetration test, by its nature, probes through a product (producing a hole in its path). Sometimes small cylinder probes/needles are used to assess, for instance, the aerated or laminated structure of a baked product, as they are effectively more sensitive than a test which crushes (compresses) the whole sample.

c) A smaller cylinder probe reduces the measured force if a test exceeds the load cell capacity, e.g. for hard candy, and may be, for some products, the only possible way to test given a force limitation situation.

Rupture force and Gel strength/bloom strength are characteristics that can also be measured during a penetration test and relate to firmness of a sample.

Bulk Penetration

However, firmness/softness can also be derived from testing in other manners such as extrusion or shearing.

Extrusion

The physical nature of some products make them more suitable for testing via an extrusion test. This test is for products that are not self-supporting and obviously limited to those products that can be extruded (i.e. generally fluid products) and is naturally unsuitable for such 'dry' products as e.g. breakfast cereals and bread. Generally, the higher the force to extrude, the firmer the sample. Learn more about extrusion tests.

Cutting

The physical nature of some products make them more suitable for testing via a cutting test. Generally, the higher the force to cut/shear, the firmer the sample. Learn more about cutting/shearing tests.

Bending

The physical nature of some products make them more suitable for testing via a bending test. Generally, the higher the force to bend (usually up to the point of break), the firmer the sample. Learn more about bend tests.

Typical comparison of samples

Single penetration

Multiple penetration

Sample with multiple textures/layers

For samples with, for example, soft centre fillings, the thickness and firmness of the filling can be determined from the graph as shown below.

How to interpret the Texture Analyser graph

When measuring firmness/softness, the force vs distance/time graph typically indicates firmness by the maximum force required to compress/penetrate the material. From the graph you can observe/obtain the following:

- Firmness

- Softness

- Work of penetration

- Work of compression

Single penetration

Typical curve indicating key analysis points of a single penetration firmness/softness test

Typical curve indicating key analysis points of a single penetration firmness/softness test

Typical curve indicating key analysis points of a multiple penetration firmness/softness test

Typical curve indicating key analysis points of a multiple penetration firmness/softness test

Full explanation of these curves and their analysis can be found within Exponent Connect software.

Below is an example of how we can help you understand curve analysis for an example property.

Notes of curve shapes

Plateau after initial rise: Often seen in foams or cellular structures, indicating collapse of cell walls.

Sharp, narrow peak: Indicates a firm, brittle sample that fractures easily.

Broad, rounded peak: Suggests a softer, more pliable sample.

Multiple peaks: A smooth curve indicates uniform texture, while irregularities or multiple peaks may suggest non-homogeneous or layered structure. The presence of air pockets will be indicated by drops in force (troughs) as the probe encounters a loss of resistance whereas the presence of particulates or the breaking through of layers will be indicated by multiple peaks. Linear distance measurement over the same region of the curve will allow sample comparison of homogeneity – a longer line will indicate a non-homogeneous nature, a smoother line will be shorter.

Key factors affecting firmness/softness measurement

- Temperature: Temperature significantly influences firmness/softness measurements, as higher temperatures generally lead to softer materials while lower temperatures result in increased firmness.

- Humidity: Humidity levels can alter the moisture content of samples, potentially changing their firmness/softness properties, with high humidity often leading to softer textures.

- Test speed: The rate at which force is applied during testing can influence the measured firmness/softness, as materials may respond differently to varying speeds of deformation.

- Compression distance: The extent to which a sample is compressed affects the force-displacement curve and resulting texture analysis, with greater compression distances typically revealing more about a material's firmness/softness profile.

- Probe geometry: The shape and size of the probe used can significantly impact firmness/softness measurements, as demonstrated by studies showing that different probe designs (e.g., chamfered vs pointed) can produce varying correlations with material strength properties.

Optimising firmness/softness measurement and analysis: The Stable Micro Systems advantage

The Stable Micro Systems Texture Analyser stands out in optimising firmness and softness measurements through its versatile capabilities and precision. It offers a range of testing methods including compression, penetration, extrusion, and cutting, allowing for comprehensive analysis across diverse product types.

The Texture Analyser’s high-precision force measurements, coupled with detailed force-time-distance profiles captured by the Exponent Connect software, provide in-depth insights into firmness and softness characteristics. Its customisable test parameters ensure adaptability to various materials, while simultaneously assessing related properties like spreadability and consistency.

Conforming to industry standards, the Texture Analyser delivers reliable, comparable results across food, pharmaceutical, and industrial applications. This combination of versatility, precision, and comprehensive analysis, backed by Stable Micro Systems' expertise, makes it the ideal choice for industries seeking to refine product formulations and maintain quality standards in firmness and softness testing.

A choice of test probes and test types to imitate consumer interaction of single and multi-particle samples.

Comprehensive multiple property analysis of graph features with micro-level accuracy in force and distance.

Ability to additionally capture synchronised video for better understanding of product behaviour.

Adjust settings to match specific product requirements or simulate real-world usage conditions.

If you need help with your firmness/softness measurement, we offer unrivalled support.

Be guided through the steps to successful testing and analysis of firmness/softness.