Measuring the Volume, Density and Dimensions of Bakery Products

The future of bakery product volume measurement

What is the purpose of measuring volume?

Loaf volume is the principal component of, and is of paramount importance to, bread quality evaluation.

This is a vital aspect of the consumer’s perception of value, because in bread and other leavened goods, higher volume – for the same weight – is invariably associated with more aerated crumb and superior texture.

For a baker or bread manufacturer, each batch of flour has to be evaluated by test baking to ensure that bread is made to a uniformly high quality. One component of this quality control is measurement of the volume of the bread, which can give information relating to the density of the bread crumb and the strength of the gluten in the flour. Lack of volume generally indicates the use of a weak flour, or one low in enzyme activity.

A very strong flour may also produce a loaf of small volume, which would indicate the need for a longer fermentation period during which the gluten would become ripened and so more extensible. This volume information can then be used to modify the dough mix used in bread production, in order to produce bread of the appropriate quality. This procedure is important, not only for the inherent qualities of the bread, but to ensure that the selected dough-piece weight produces a loaf of the correct size for the standard tins used in the baking process.

The baked product must also be capable of being handled by automatic slicing machines and packed into standard sized bags. It is therefore important to have a precise and rapid method for the measurement of the volume of bread loaves, enabling control and monitoring of bread-making conditions and manufacturing operations.

The Volscan Profiler – allows measurement, analysis and comparison

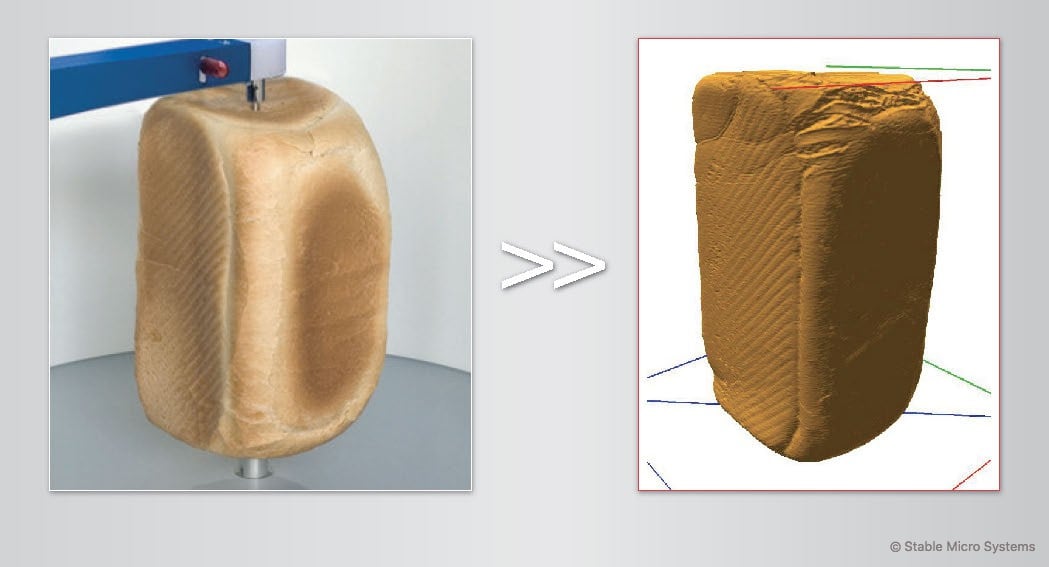

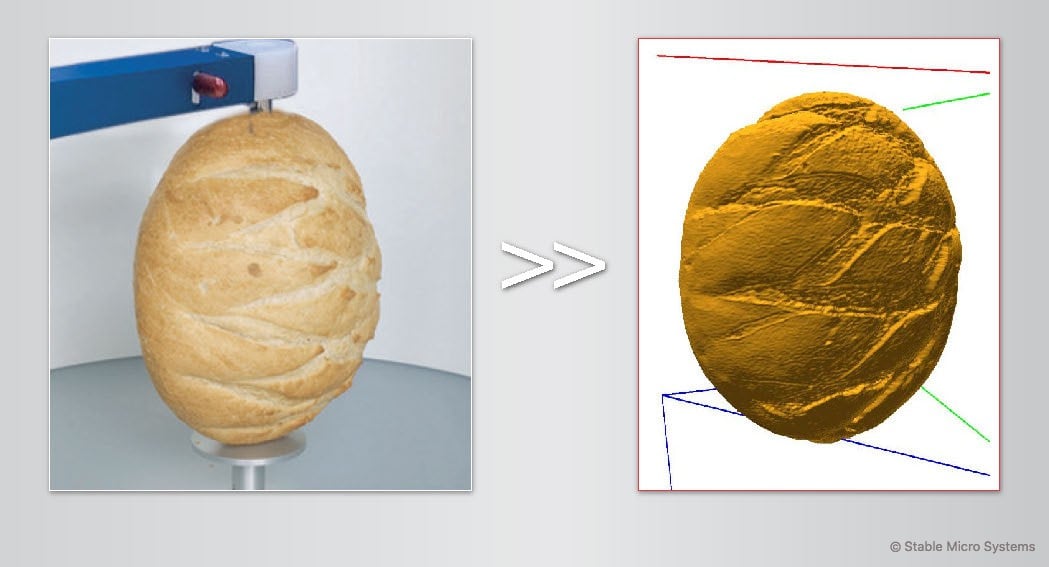

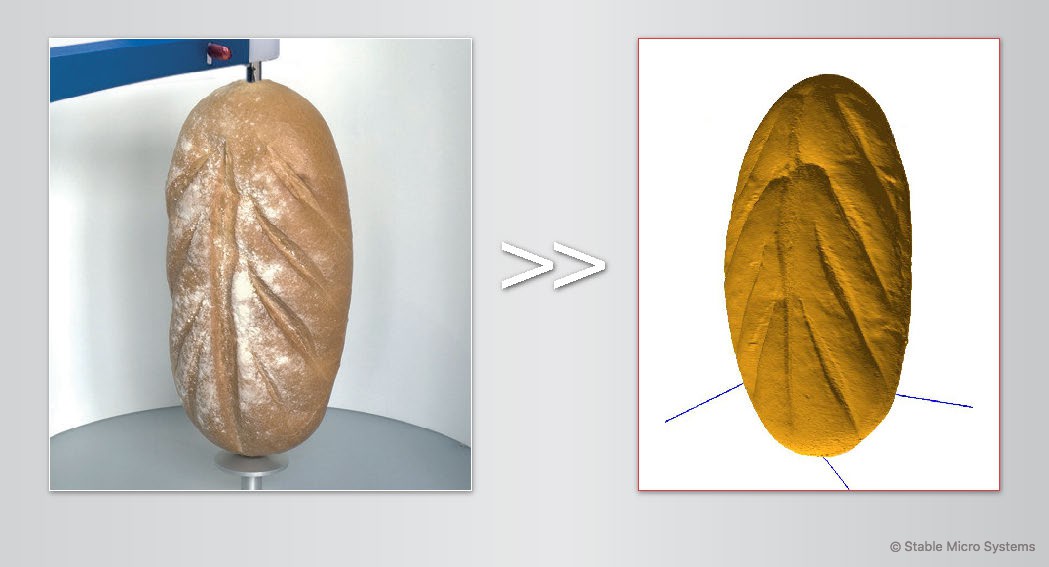

The Volscan Profiler is a benchtop laser based scanner that measures the volume of bread and bakery products with maximum dimensions of 600mm long and 380mm diameter, with a typical test time of less than 60 seconds.

Instead of just assessing the volume as with seed displacement methods, the Volscan Profiler has the ability to automatically measure and calculate and additional 19 related parameters, such as height, width, length and weight. It also enables the rapid 3-dimensional digitisation of products which can be archived and then treated mathematically to yield detailed dimensional information for immediate use or future retrieval.

This instrument rapidly provides the accurate data essential in the fields of both Quality Control and Product Development.

Things you couldn't test using seed displacement...

Traditionally, volume measurements of baked products have been obtained by the technique of seed displacement, in which the amount of rape seed or pearl barley packing around the loaf in a standard container is measured.

Whilst this method has been universally recognised for decades as indicative of baking quality, it is now considered primitive, inaccurate, tedious and laborious. Repeated calibration, operator dependence, loss of rapeseed due to spillage/adherence of seeds to the product or to static electricity, seed clumping due to moisture absorption, periodic sieving of the seed to remove food crumbs, the potential crushing of soft products and the manual recording of results are the common drawbacks affecting both the efficiency and the accuracy of the measurement.

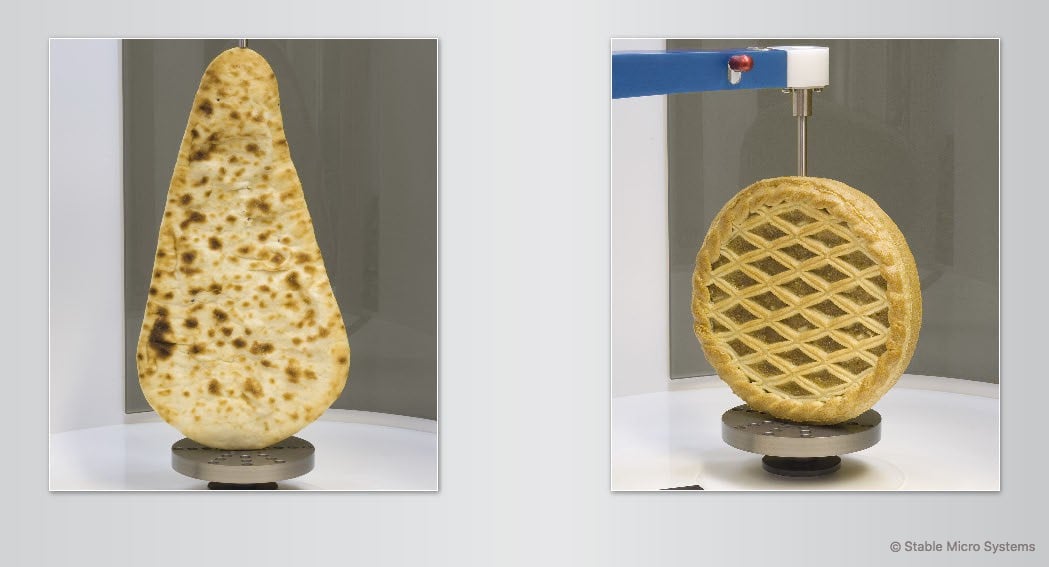

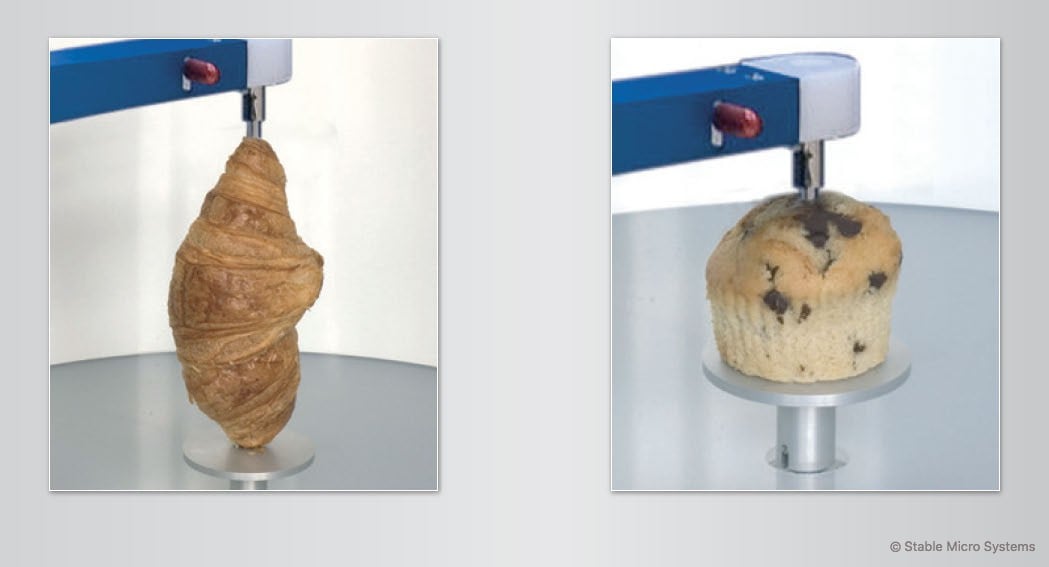

Besides offering rapid 3-dimensional digitisation of products, it has the ability to measure objects that, due to their texture or size, was not possible with seed displacement. Soft, thin or brittle products with vulnerable structure due to toppings, or being easily altered by the compressive nature of seed displacement are easily mounted on the Volscan Profiler by a variety of supporting pins.

AACCI Approved Method 10-16.01

The Volscan Profiler has been awarded the certificate of approval as an AACCI Standard Method with reference 10-16.01. This is good news for all operators in the cereal science and bakery product testing world who are encouraged to use (or have greater preference for) methods that are approved by the AACCI.

The Method was taken through a collaborative study with 9 other laboratories in 4 countries who followed the procedure and reported their results from the measurement of the same samples. The measurement of Volume, Length, Height and Width are all part of the Standard Method, making it the most accurate approved method with more scope in parameters and breadth of bakery samples than any similar method using competitive equipment.

Measuring so much more than Volume

For those manufacturers of sandwich loaves looking to verify whether their finished diagonally cut sandwiches will fit in the chosen packaging, the determination of maximum height and width will qualify their suitability to fit without difficulty.

For manufacturers of baguettes and rolls, a further calculation – ‘Minimum Enclosing Circle’ – is also now available to measure the minimum diameter of packaging that is required to contain the product without deformation. The smallest circle that can encompass all of the data points of the largest scanned slice is virtually fitted to the finished scanned product.

By customer request, we have also added the measurement of Surface Area, testament to the fact that the software is constantly evolving to include features required by users of this field of measurement.

Additional parameters and calculations can also be defined by the user if required. This provides the option of adding your own calculations and data references into the Volscan software to optimise the information you wish to include in reports. The addition of all of these unique calculations extends the useful application of the Volscan Profiler and provides extra manufacturing decision tools not offered by any alternative or historically available volume measuring method.

In a fast paced baking industry, rapid product measurement and provision of automatically calculated quality control pass or fail benchmarks is key to manufacturing intelligence and success.

No other instrument is as comprehensive in its measurement parameters as ours – we measure so much more than volume.

1

1 2

2 3

3 4

4 5

5